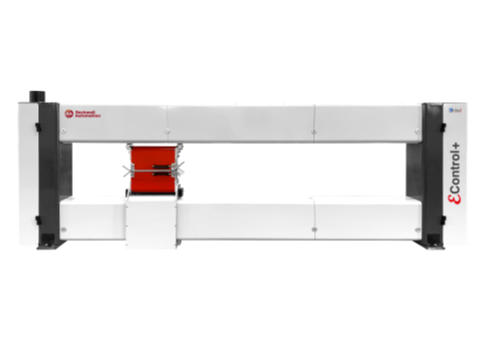

QCS O-FRAME

QCS (Quality Control System) è un apparato che consente di misurare in continuo le caratteristiche del prodotto nel momento stesso in cui esce dai macchinari, senza interferire con il processo produttivo a ciclo continuo. Nel mercato attuale, l’esigenza di controllare e certificare la qualità del proprio prodotto è stringente per tutte le industrie, in special modo di quelle cartarie, anche se piccole e che quindi non hanno la disponibilità di grossi investimenti propria delle realtà maggiori.

Questo è il principio che ci ha guidati nella progettazione del nostro QCS: proporre uno strumento affidabile sempre, ad un livello di prezzo accessibile anche alle realtà più piccole ma senza scendere a compromessi sulla qualità.

La possibilità di personalizzazione dei nostri dispositivi rende il prodotto adatto sia alle applicazioni di base, che alle applicazioni in realtà grandi con esigenze complesse come, ad esempio, catene di produzione che necessitano dell’interfacciamento con DCS sia di nostra fornitura che preesistenti.

Questo è il principio che ci ha guidati nella progettazione del nostro QCS: proporre uno strumento affidabile sempre, ad un livello di prezzo accessibile anche alle realtà più piccole ma senza scendere a compromessi sulla qualità.

La possibilità di personalizzazione dei nostri dispositivi rende il prodotto adatto sia alle applicazioni di base, che alle applicazioni in realtà grandi con esigenze complesse come, ad esempio, catene di produzione che necessitano dell’interfacciamento con DCS sia di nostra fornitura che preesistenti.

CARATTERISTICHE:

Un sistema di controllo della qualità estremamente efficiente si traduce in un’ottimizzazione del processo produttivo.

I nostri QCS sono interamente customizzabili a misura degli impianti di produzione, delle tipologie di controllo da effettuare sulla lavorazione.

Il ridotto ingombro del sistema da assemblare permette un facile montaggio all’interno delle aree di produzione e consente il trasporto alla destinazione di utilizzo con mezzi di portata moderata.

I sistemi di controllo di qualità consentono il monitoraggio a qualsiasi velocità di produzione.

ECS Plus è un sistema totalmente integrato, progettato per soddisfare le crescenti necessità del processo di fabbricazione della carta, sempre più orientate verso il raggiungimento di una migliore qualità e di una maggiore efficienza energetica.

La diffusione di nuove tecnologie e la lunga esperienza maturata nel campo di applicazione di QCS e DCS ci ha permesso di realizzare un sistema di misura e controllo che utilizza i più recenti traguardi nel campo dei componenti, dei sistemi di sviluppo e delle tecniche di applicazione.

La elevata qualità dei materiali usati nella costruzione dei ponti di esplorazione e la solida architettura hardwareutilizzata, garantiscono un’elevata affidabilità e una semplice e rapida manutenzione preventiva.

Regolazioni automatiche in senso macchina e trasversali possono essere implementate insieme a quelle di cassa d’afflusso, seccheria, preparazione impasti, raffinazione, etc.

SOFTWARE

Tutti i dati storici possono essere archiviati e consultati permettendo la creazione di report analitici.

L’interfaccia software di semplice intuizione e utilizzo permette una comoda gestione dei fattori produttivi interessati.

SISTEMA DI BORDOFOGLIO AUTOMATICO

SISTEMA DI PULIZIA SUPPLEMENTARE